Slicer (for Slicing Meat) Maintenance Guide

May 15,2025

254

The slicer is a helpful assistant in the kitchen for processing meat slices. Whether it's in a hot pot restaurant, a barbecue restaurant, or a home kitchen, using it can quickly cut out even and beautiful meat slices. However, if you want the slicer to operate stably for a long time and maintain a good cutting effect, proper maintenance is essential.

Next, we will introduce in detail the maintenance methods of the slicer.

I. Daily Cleaning

After each use of the slicer, timely cleaning is a basic and crucial step. First, cut off the power supply to ensure operational safety. Use a soft cloth or brush to carefully clean the meat slices, meat crumbs, and other debris remaining on the surface and inside of the slicer to prevent them from drying and becoming difficult to remove. For the blade of the slicer, extra care is needed. You can use special cleaning tools, such as a sponge or soft cloth, along with a mild detergent to gently wipe the surface of the blade. Note that never use sharp tools like steel wool for cleaning, as it may scratch the blade and affect the cutting effect. After cleaning, wipe the machine with a clean damp cloth to remove detergent residues, and then dry it with a dry cloth to avoid water stains remaining and causing the machine to rust.

II. Maintenance of Key Components

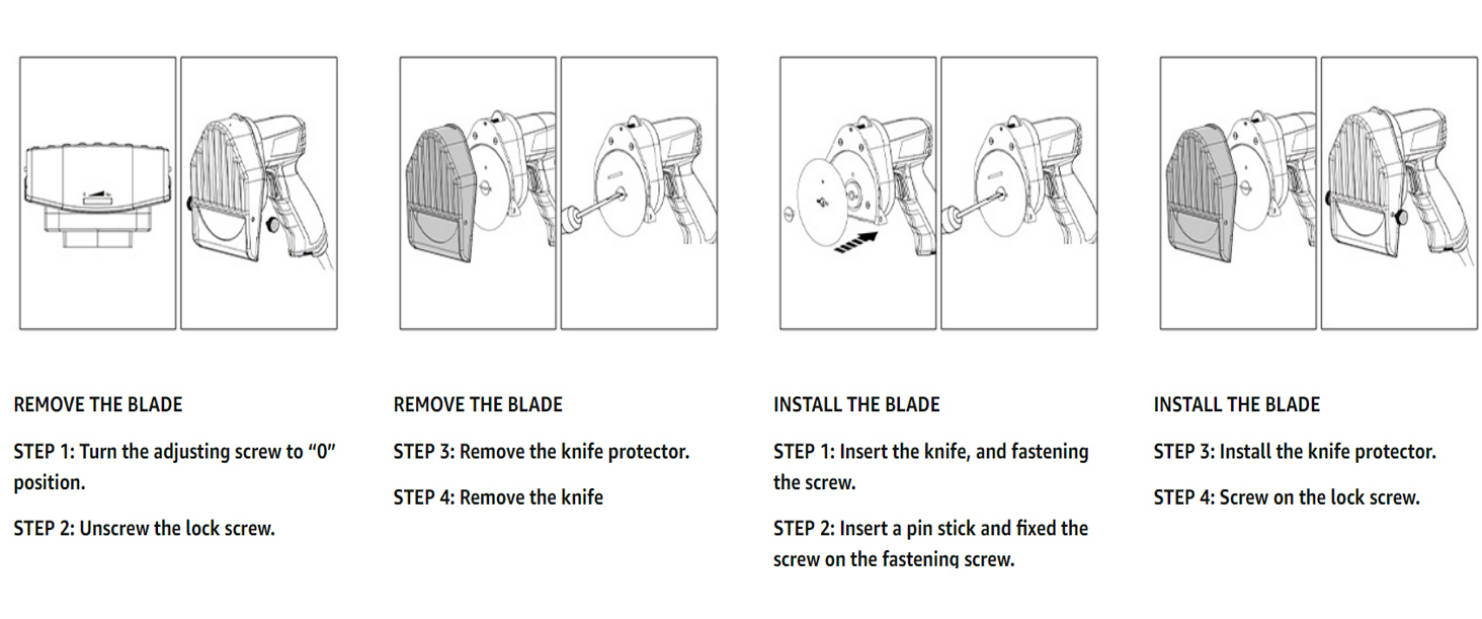

The blade, as the core component of the slicer, directly affects the slicing quality and efficiency, and regular maintenance is of great importance. Check the sharpness of the blade at regular intervals. If you find that the blade becomes dull and the sliced meat sticks or is uneven, it needs to be sharpened in a timely manner. When sharpening, use professional sharpening tools and follow the correct operating methods to ensure the flatness and sharpness of the blade. In addition, the fixing screws of the blade should also be checked regularly to ensure they are tightened, preventing the blade from shaking due to loose screws during use, which may lead to safety accidents.

Besides the blade, the transmission components of the slicer, such as gears and chains, also need to be lubricated regularly. According to the frequency of use of the slicer, apply an appropriate amount of special lubricant to the transmission components at regular intervals to reduce the friction between components, reduce wear, and ensure the normal operation of the slicer. At the same time, regularly check whether the transmission components are worn or loose. If there are any problems, replace or repair them in a timely manner.

III. Usage Specifications and Storage

When using the slicer, strictly following the operating specifications can effectively reduce machine wear. Do not overload the slicer and avoid cutting overly hard or thick ingredients to prevent damage to the blade and the internal structure of the machine. At the same time, place the ingredients correctly to ensure they are stable, preventing the ingredients from sliding during the cutting process, which may affect the cutting effect and even cause safety hazards.

When the slicer is not used for a long time, proper storage should be ensured. Clean the slicer thoroughly and place it in a dry and ventilated environment to avoid damage to the machine caused by moisture and dust. If conditions permit, you can also cover the slicer with a dust cover to further protect the machine.

The maintenance of the slicer needs to start from multiple aspects, including daily cleaning, maintenance of key components, standardized use, and reasonable storage. Only by doing these maintenance tasks well can the slicer always maintain good performance, provide us with efficient and high-quality slicing services, extend its service life, and reduce maintenance costs and replacement frequency.